Ceratizit on track for record breaking year

Despite a feeling of general turbulence in the industry, some companies are performing incredibly well. Take Ceratizit UK & Ireland for example which is on track to have its best ever year. Not only that, but the tooling specialist also ended 2023 on a real high with an insanely busy open house in December which saw 150 visitors pass through its doors – one of which was Dave Tudor.

You can always have too much of a good thing so Ceratizit doesn’t tend to host open houses often. In fact, the December 2023 event was only the second open house held at the company’s Technical Centre located on the Advanced Manufacturing Park in Sheffield. The first, which took place in October 2021, also marked the official opening of the facility. The common denominators for both events were extremely high visitor interest, loads of product demos and plenty of technology on offer.

Going for gold

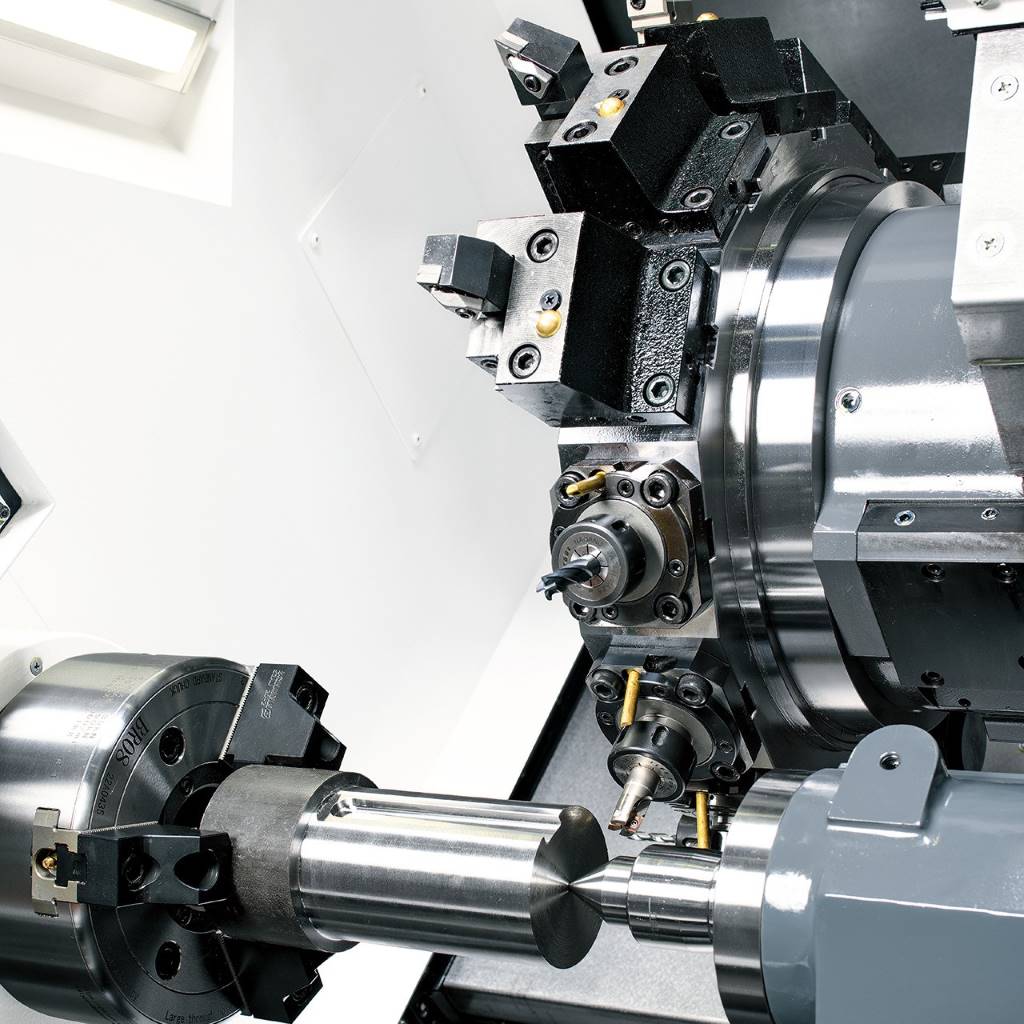

Like, for example, Ceratizit’s new range of ISO-P multi-edged indexable carbide turning inserts with wear detection which were put through their paces on a Mazak Integrex i-250H multitasking machine in the Tech Centre during the open house – a machine that combines turning with 5-axis milling.

The demonstration showcased various products from the range: CNMG for end facing and roughing the O/D; RCMT button inserts for the trochoidal turning of a recess; and DNMG for finish turning.Ceratizit’s ISO-P inserts comprise a wear-resistant grade with a high degree of elevated temperature resistance for machining steel at high cutting speeds. Different grades are available for individual cutting conditions including roughing, medium machining and finishing and all have a Dragonskin coating to reduce friction and prevent and identify wear.

An interesting aspect of these ISO-P (the ‘P’ denotes performance) inserts is a gold-coloured outer indicator layer so operators can physically see how the tool is wearing in real-time. This forms part of a triple layer arrangement comprising: a Ti (C, N) highly textured base layer; an Al2O3 multilayer; and the gold-coloured TiN outer layer.

“Cutting ISO-P steels can be challenging but due to improved layer performance the new inserts represent up to 45% longer tool life compared to our older grades depending on cutting speed,” explains Ceratizit UK & Ireland’s technical manager Shaun Thornton.

“Our customers appreciate the gold indicator layer because it clearly shows when the edge is wearing and needs to be changed. The main benefit is that cutting edge life can be optimised. With the older black inserts, wear was much more difficult to detect. The gold layer offers no performance enhancements per se; it’s purely a visual indicator.”

Know the drill

Solid carbide drills can be frighteningly expensive – especially in larger diameters – so readers will no doubt be keen to learn that Ceratizit’s new WPC change drill offers all the performance of a solid carbide drill in terms of cutting data, but it features an interchangeable indexable insert tip. This means you only have to change the insert rather than the entire drill which is far more cost-effective.

“This product is manufactured by Komet which is part of the Ceratizit Group,” Mr Thornton explains. “Unlike a solid carbide drill, the body holder is steel which offers a degree of flex when machining – and you get full twist drill geometry. WPC holders and inserts are available in a wide range of diameters from 14mm to 30mm and in lengths of 3 and 5xD,” he adds.

For deep hole drilling applications, Ceratizit’s WTX high performance deep hole drills can now drill to depths of 50xD with an appropriate pilot hole. With diameters spanning 2mm to 12mm, the design ensures excellent chip evacuation and alignment precision.

Closed loop quality assurance

Machine. Measure. Correct: the Komflex measurement system is a joint collaboration between Ceratizit and measurement and testing technology specialist Blum-Novotest. The system was demonstrated at the open house on an XYZ UMC-5X 5-axis machine.

This is an all-encompassing closed loop boring system that combines production with quality assurance. It comprises a Ceratizit fine boring head which communicates with the Blum’s measuring stylus wirelessly through its RC66 interface, effectively enabling automatic, in-process diameter correction on holemaking and boring processes (6-120mm diameter range). The spindle head and Blum system are initially paired like any other wireless devices.

Aside from the obvious advantages of reducing production times and avoiding scrapping eye wateringly expensive parts, the cost saving implications are significant – and this, plus live machining data is visible via a user-friendly, downloadable Amortisation app accessible through the machine tool’s CNC. It really is a case of machine, measure, correct.

And because Komflex is a highly secure, closed loop system, it can run unattended, requiring little or no manual intervention. There’s virtually no chance of human error and it can even reinitialise the tool or instigate a change after predetermined wear limits are reached. Literally set the parameters and go.

Tool management: the best of both worlds

Like practically all tooling companies, Ceratizit offers its own tooling cabinet management system called ToolSupply Tool-O-Mat. This is a closed system and is totally managed, restocked and audited by Ceratizit on behalf of its customers. Now however, Ceratizit has introduced a brand new, hot off the press open tool management system called MyTOM. Shaun Thornton explains.

“The advantage with open systems is that the customer, not Ceratizit, manages the stock on equipment they’ve already bought,” he states. “MyTOM needs our Tool-O-Mat 840 closed system to work but it means that items like partially used tools, gauges, measuring equipment, PPE, tool regrinds and cutter bodies can be booked back into the system rather than finding themselves ‘lost’ in operator toolboxes or worse still, thrown away.

“You can partially use a tool for example and then return it back to stock so it becomes controlled again.”

MyTOM is essentially a separate cabinet that’s linked to a Tool-O-Mat 840 system (it can’t operate standalone) so customers can get the benefits of owning both a closed and open tool management system. Ceratizit takes care of the Tool-O-Mat cabinets; the customer manages MyTOM.

The latter has its own browser-based operating software that can be accessed via a desktop computer, laptop or mobile device so taking items out of stock and booking them back in (if applicable) is an absolute breeze.

Tech Centre evolution

Since its inauguration in 2021, the Technical Centre has been a phenomenal success for both Ceratizit and partner XYZ Machine Tools. It’s used mainly for customer projects, speccing out the right tools for the job in hand.

“It’s all about working closely with our customers and making their lives easier,” Mr Thornton affirms. “Sometimes they’ll simply send in a drawing and we’ll work from that; or other times the customer will come here and we’ll work through things together.

“Since we opened the centre, it’s been very busy. Both ourselves and XYZ use the facility extensively and there are always a large number of projects running at any one time. We also use it as a training facility for our staff on new product introductions, our apprentices and even customers. The skills shortage has affected everyone, and we often find our clients need an extra helping hand. For us it’s all part of the service.”

At the moment, Ceratizit occupies two sites in Sheffield approximately two miles apart – but not for much longer because the plan is to move both operations to a single site in 2026. Work is already underway in locating a suitable location.

Laying the foundations for continued success

I mentioned at the top of this article that Ceratizit UK & Ireland is on track for a record year. The company’s financial year runs from 1st March to 28/29th Feb and for 2023/24 turnover is set to top a staggering £45 million. Remember this is a tooling company – not a capital equipment manufacturer that can sell a machine tool for £1m+. Quite an achievement.

“I am delighted to report that Ceratizit UK & Ireland will reach a turnover level of £45m+ this year which represents year on year growth in excess of 15%+,” enthuses Tony Pennington, Ceratizit’s managing director, cutting tools North Europe.

“I believe this is down to several factors: the strong customer relationships built by our long established, 42 strong team of engineers who are supporting clients on a daily basis to provide solutions that save them time and money.

“In addition, the further investment we have made in our UK stock to hold over 8,500 lines of our fast-running tools providing a guaranteed next day before noon delivery has given another advantage to our customers. Furthermore, our free of charge vending solutions, providing 24/7 access to tools with full control helps keep our customers’ spindles turning.

“We work extremely hard to provide what we believe to be the best customer service in the industry,” he concludes. “We’ll continue to invest in people and technology to drive the company forward year on year.”

Ceratizit UK & Ireland

www.ceratizit.com