MACH 2024: Mills goes out of this world

Mills CNC is to showcase what it describes as a stellar array of advanced high-productivity machine tools and automation systems on its stand at MACH 2024.

Continuing the interstellar theme, a total of 16 star-studded machines will be on display, including a number making their UK and MACH show debuts. Two automated manufacturing cells will complete the Mills technology line-up, on what will be the largest stand at the event (750m²).

The company’s technology line-up includes eight milling machines (seven DN Solutions 3- and 5-axis vertical and horizontal machining centres, and a large-capacity Zayer horizontal CNC bed mill, seven DN Solutions lathes and turning centres and a DN Solutions SMX multi-tasking mill-turn machine. Two of the turning centres being showcased form the mainstay of two separate automated manufacturing cells.

“Our stand at MACH 2022 with its Broadway theme, is still being talked about in industry circles, and raised the bar in terms of creativity and stand design,” says Tony Dale, Mills CNC’s CEO. “As part of our commitment to continuous improvement, we are confident that we have gone one better this time around with our MACH 2024 Space Odyssey themed stand.”

First contact: show debuts

Five of the machines on Mills’ stand are new models that are making their MACH show debuts. Pride of place, and occupying the largest space on Mills’ stand, will go to the new Zayer XIOS G CNC horizontal bed mill. This large-capacity machine is equipped with a built-in rotary table (1,500mm by 1,500mm), a 5-axis, 45â° milling head and the latest Heidenhain control.

With its powerful, high-torque spindle (40kW/6,000rpm), and impressive positional accuracy (0.008mm) and repeatable accuracy (0.005mm) capabilities, the XIOS G is ideal for large aerospace, rail, energy and oil and gas part processing, including mould and die applications.

New DN Solutions machines making their MACH 2024 debuts include the compact, FANUC-controlled DVF 4000 simultaneous 5-axis machining centre, two models from the recently launched DNT-series of high-performance lathes (DNT 2100M and DNT 2600), and a PV 9300M vertical turning lathe.

The DVF 4000 is the latest addition to DN Solutions’ popular DVF-series of simultaneous 5-axis machining centres and is equipped with a 12,000rpm spindle, a 400mm diameter, built-in rotary tilting table and a 60-position ATC. Roller LM guideways and integrated thermal compensation help make the DVF 4000 a fast, precise, powerful and reliable 5-axis machine tool solution.

DNT 8/10-inch chuck, box guideway lathes were introduced into the market in early 2023 and are well represented at the show. The FANUC-controlled DNT 2100M has an 8-inch chuck/65mm bar diameter and is equipped with an 18.5kW/4,500rpm spindle, a 12-station turret and driven tooling capabilities (up to 10,000rpm). The DNT 2600 is a 10-inch chuck/81mm bar diameter lathe, equipped with a 26kW/3,500rpm spindle, and 10-position turret.

The PV 9300M is a robust and powerful 24-inch chuck vertical turning lathe with 20m/minute rapids (X- and Z-axes), a 45kW/1,800rpm spindle, a 12-station turret, 4,000rpm driven tooling capability and an additional, front-mounted ATC for extra productivity.

The right stuff: established crowd pullers

In addition to new machines making their debuts, Mills’ stand also features a number of popular and bestselling models from its well-established machining centre, turning centre and mill-turn machine ranges.

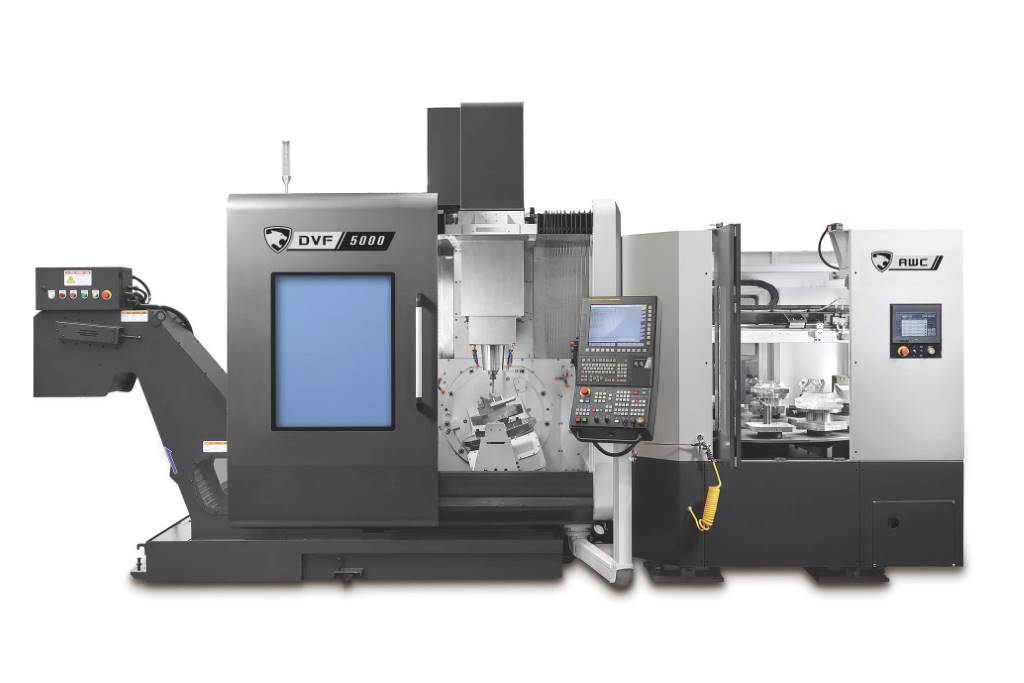

For example, the company is exhibiting two DVF 5000 simultaneous 5-axis machines on its stand – one standalone model and one integrated with a multi-level automated pallet change system.

Other milling favourites on show will include three DNM vertical machines centres: a DNM 4500 with Siemens control, a DNM 5700 with FANUC control, and a Heidenhain controlled DNM 6700, and a NHP 5000 horizontal machining centre integrated with an automated pallet changer.

“Increasingly, manufacturers are looking to increase their competitiveness by embracing automation,” Mr Dale says. “As a leading automation system supplier, we are showcasing a number of DN Solutions machines integrated with pallet change systems which can significantly improve customers’ productivity by enabling them to take advantage of unattended and lights-out operations.”

Helping customers improve their productivity and process efficiencies were major factors in determining the turning centres and mill-turn machines Mills has decided to showcase on its stand.

A multi-tasking 8-inch chuck Lynx 2100LYB with integrated Y-axis capability has pride of place alongside a newly introduced 10-inch chuck TT 2100SYYB, twin-turret/twin-spindle turning centre with dual Y-axis functionality, and a 10” chuck SMX 2100SB mill-turn machine equipped with left and right opposing spindles and a B-axis milling spindle.

Ad Astra: automated robot cells

In recent years, Mills CNC has gained a reputation for supplying manufacturers with productivity-enhancing automated manufacturing cells. At MACH 2024, the company is reinforcing its automation and turnkey solution credentials by showcasing two robot cells on its stand.

The first of these, a SYNERGi Premier cell, comprises a 12-inch chuck Puma 3100SY sub-spindle, Y-axis turning centre integrated with a FANUC industrial robot, a five-drawer, bi-directional, part load/unload station and a 17-inch touchscreen iHMI. The cell is driven by Mills’ proprietary SYNERGi software.

The second cell, incorporating a compact 10-inch chuck Lynx 2600SY sub-spindle, Y-axis lathe, is integrated with a collaborative robot, and will be undertaking a range of machine tending operations.

“Manufacturing cells, using either industrial or collaborative robots, help customers achieve continuous production by unlocking the true productivity potential of their machine tools,” Mr Dale explains.

Training days

In addition to the 16 machine tools on view, the company will also be promoting its full range of CNC programmer and operator training courses offered by the CNC Training Academy.

The Academy, which has recently relocated its entire operation to new, modern premises at the company’s campus facility in Leamington, will demonstrate how its comprehensive ranges of FANUC, Siemens and Heidenhain training courses, as well as its advanced and specialist FeatureCAM, BobCAD-CAM, Manual Guide I and Custom Macro course provision, can help manufacturers ensure machining best practice, get more from their machine tools, and combat internal skill shortages by training-up their existing workforce, providing employees with relevant and transferable skills.

Mills CNC

www.millscnc.co.uk

Hall 19, Stand 110